- ABOUT CTC

- EXPERTISE AND SERVICES

- Raw hide - Tannery

- Footwear

- Leather goods - Glove-making

- PPE

- Environment

- CSR

- Training

- BLOG AND NEWS

- CTC VIDEOS

- LEAFLETS AND PUBLICATIONS

- CUSTOMERS EXTRANET

EN

The process by which a chemical move through a physical barrier (it can be a textile or a polymer material for example) on a molecular level.

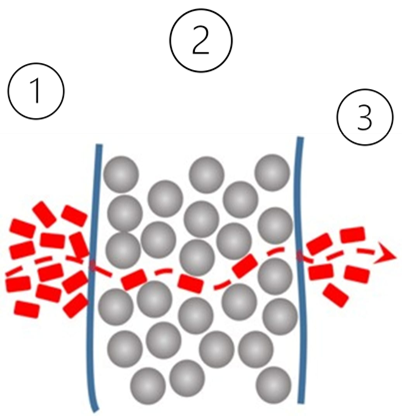

Majorly 3 physico-chemical phenomena are involved in permeation:

This process is a distinctly different mechanism than penetration where chemicals move through voids in materials without change of state.

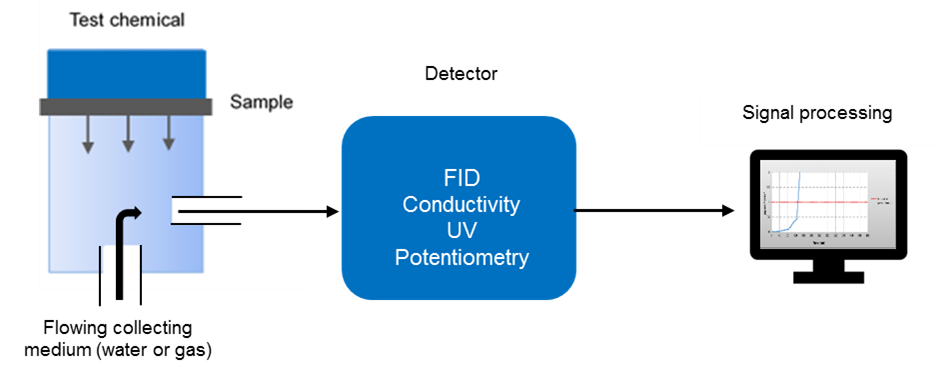

The protective property of a material against permeation by a chemical is determined by measuring the rate of permeation through the test material. Using a special testing cell, the material is exposed to a chemical in liquid or gaseous form, the mass of chemicals that has permeated through is determined analytically over a 480 min period.

Depending on the material properties, the chemical permeates through at different pace. This is the base for the comparison of materials. For this purpose, the European standard EN 16523-1:2015 + A1:2018 defines a standard permeation rate (or normalized permeation rate “NPR”) arbitrary fixed at 1.0 µg.cm-2.min-1.

With this reference value, manufacturers can compare different material’s performance by measuring the elapsed time between initial contact of the chemical with the outside surface of the material and the time at which the chemical is detected on the other side of the material at a permeation rate of 1.0 µg.cm-2.min-1. This information obtained on material is the material’s Normalized Breakthrough Time (“NBT”).[i]

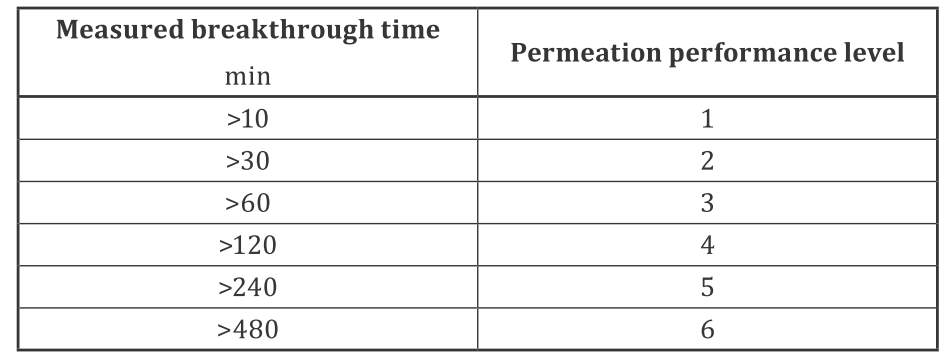

The standard EN ISO 374-1: 2017 that defines the performance requirements for chemical resistant gloves gives the performance level classification table according to the materials’ NBT:

The permeation performance level is the criteria used for the classification, the CE certification, and the marking of the PPE.

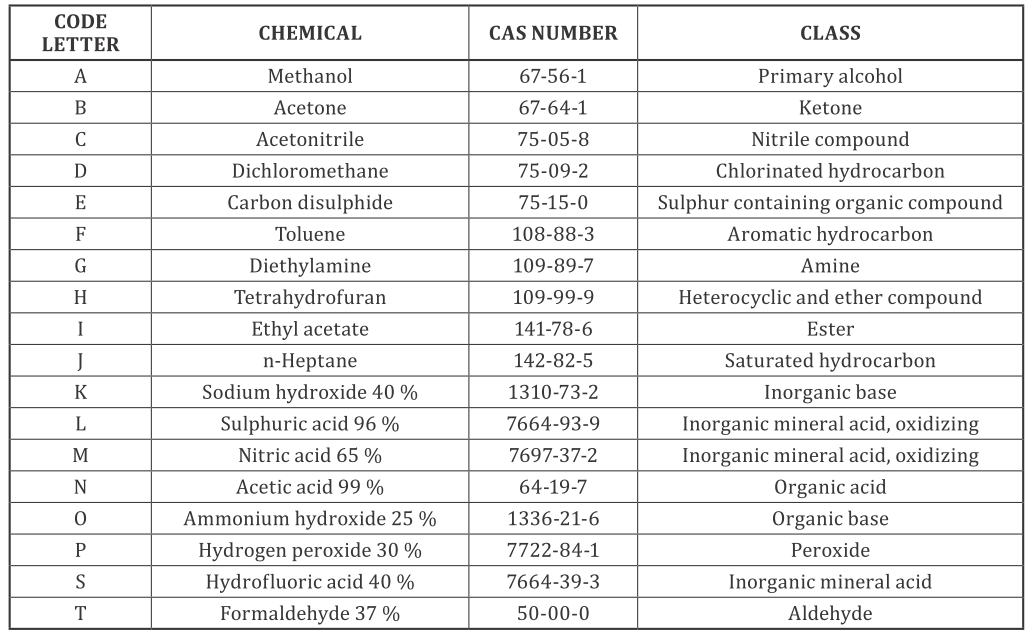

CTC laboratories accredited in France by COFRAC, and in Hong Kong by HOKLAS have developed and enhance its capacity for measuring permeation rates in PPE (gloves, garments) for those chemicals defined by permeation standards EN ISO 374-1: 2017 (see below table).

Among the many requirements set out by the PPE test standards, particular attention must be paid to those required for defining the instructions for use in particular, the information which gives the possibilities of use (single use or reusable) or the PPE maintenance and washing recommendations.

CTC teams (laboratories and certification) are at your disposal to test and certify your gloves relevant chemical risk PPE.

[i] For safety reasons, it is important to keep in mind that chemical permeation is a gradual and continuous process over time and that the NBT does not correspond to the moment when the chemical permeates first the material. NBT measurement serves only the purpose of comparing materials’ performance.