'Inspections of materials, components and finished products allows business partners to regulate their suppliers based on the detailed assessment of a qualified third party.'

Pierre Beaupoil, Vice director for development

CTC is specialized in consulting, training and in the quality control of consumer goods : mainly shoe, leathergoods, textile and clothes industry. CTC has a registered office in Lyon and several offices in Europe (France, Portugal, Spain), in Asia (China, India, Vietnam, Cambodia, Thailand, Indonesia), in the United States (Enfield, Portland) and in Africa (Tunisia).

The footwear, textiles and chemical laboratories of CTC Groupe are in France, with Hong Kong, Shanghai, Dongguan (China), New Delhi (India) and Ho Chi Minh (Vietnam).

A central structure in Shanghai deals with all the customers‘ files, follows all the inspections and customers' requests and emits the documents at the end of the inspections:

Our client expressed his need for quality control on his orders and called upon CTC for the realization of inspection in following countries:

Have your products inspected by the specialists!

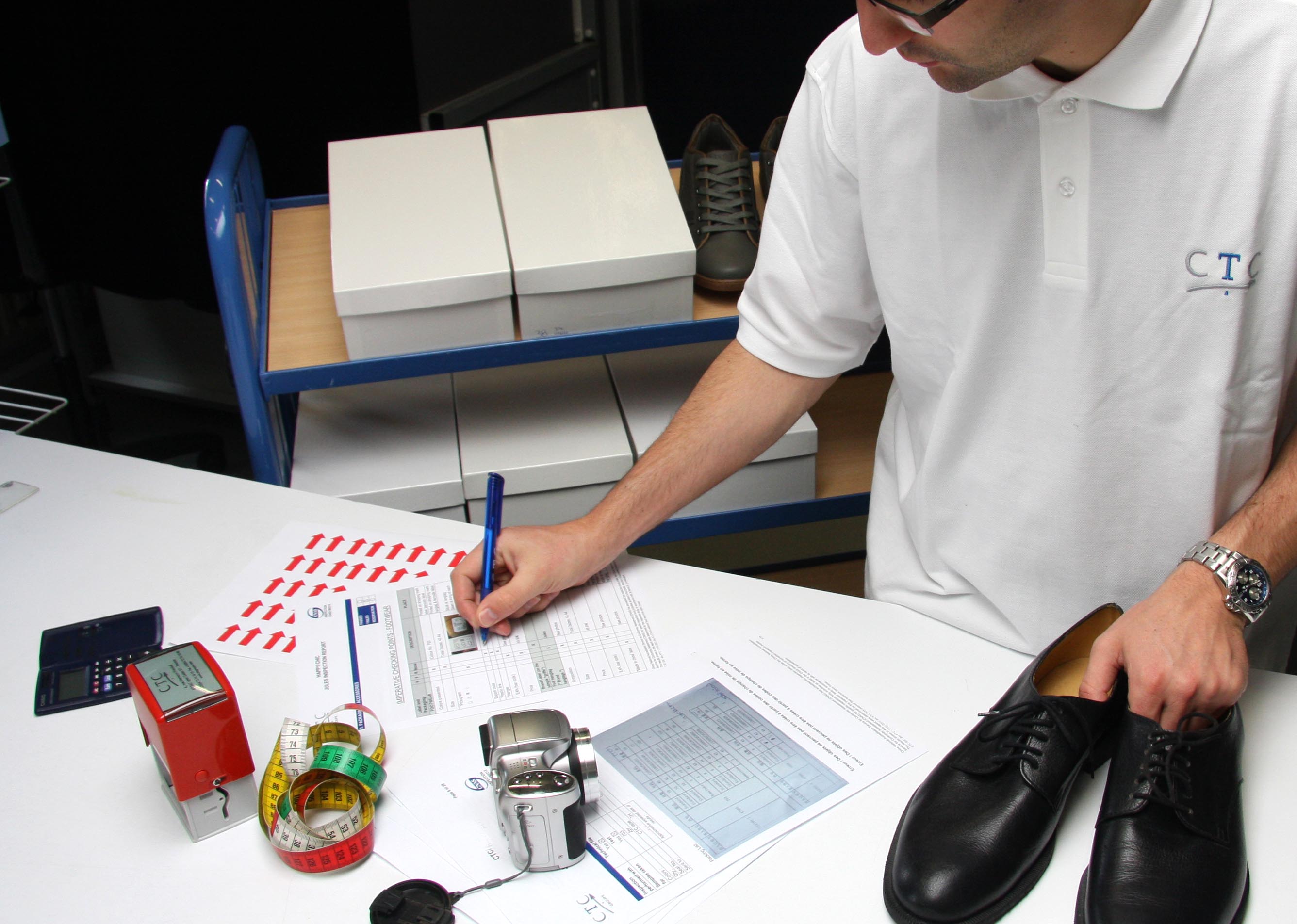

Have your products inspected by the specialists!CTC auditors are not only audit professionals, but also industrial experts in the fashion, luxury goods and sport sectors.

Clothing and accessories are the only types of consumer goods they inspect. Therefore, they understand the particularities of each type of product, whether it's a sports shoe, an item of children's clothing or a piece of luggage.

A network to cover all your sourcing needs

A network to cover all your sourcing needsOur inspections are conducted in compliance with the ISO 17020 standard and carried out in the major sourcing locations for your products: China, India, Bangladesh, Vietnam, Cambodia, Indonesia, Tunisia, etc.

Metodology of inspections and quality controle

Metodology of inspections and quality controle

The inspections are carried out according to the standard ISO 2859 (known also under the references MIL STD 105 E), recognized at the international level as being the reference and whose principal characteristics are as follows:

It consists in taking in a random way N samples of products in a batch and counting the number of defects for each category of defects or the number of products presenting one (or several) defect. If the number of defective products per category of defect is lower to the AQL defined then the batch is accepted, if it is higher than the AQL, the batch is rejected.

Definition:

A batch is the total number of products to be inspected in one or several orders.

The AQL (acceptable quality level) is the maximum percentage acceptable of defective products.

Different AQL may be applied to various types of defects. The AQL are generally indicated by category of defects.

The inspection plan will be defined, in accordance with the standard, by the inspection level and the acceptable quality levels (AQL) per category of defect.

Definition: The inspection level is the ratio between the batch size and the sample size

Levels I, II and III are the general inspections types and S2 is a special inspection level:

The inspection is a visual control which relates to the following points:

Quantity control consists in checking your orders quantities are effectively shipped but also secures:

The control of conformity consists in considering the general aspect of the product compared to the sample of conformity and to the technical file:

The quality control consists in counting the number of defective products in the sampling size and defining the category of the noted defects (critical, major, minor)

With the following classification of the defects:

We insist and precise that inspections are conformity visual checks in regards to a conformity sample and a technical file

The wear resistance as well as the mechanical solidity of the products is neither controlled nor controllable during the inspections. Only duly identified laboratory tests would make it possible to validate these characteristics.

Packing control consists :

Of strict Export Cartons control : Shipments marks, Labeling, cartons size.

Securing Key data information : Purchase order number, Cartons numbers and key boxes information, Expedition countries, etc...

Packaging controls : All necessary labels from barcodes, composition labels, pictograms to promotional labels.

Strict overview of the services : Labels, Shipping mark, antimoulding, inners quality, bags or boxes quality, fillers, etc...

It is very important to note that all repacking steps following the inspection are under the supplier’s responsibility:

Following the inspections on site, CTC will send to client an inspection report for each inspected reference, within the 24 hours following the inspection. This inspection report details the 4 control points: quantity, quality (AQL), conformity and packaging.