- ABOUT CTC

- EXPERTISE AND SERVICES

- Raw hide - Tannery

- Footwear

- Leather goods - Glove-making

- PPE

- Environment

- CSR

- Training

- BLOG AND NEWS

- CTC VIDEOS

- LEAFLETS AND PUBLICATIONS

- CUSTOMERS EXTRANET

EN

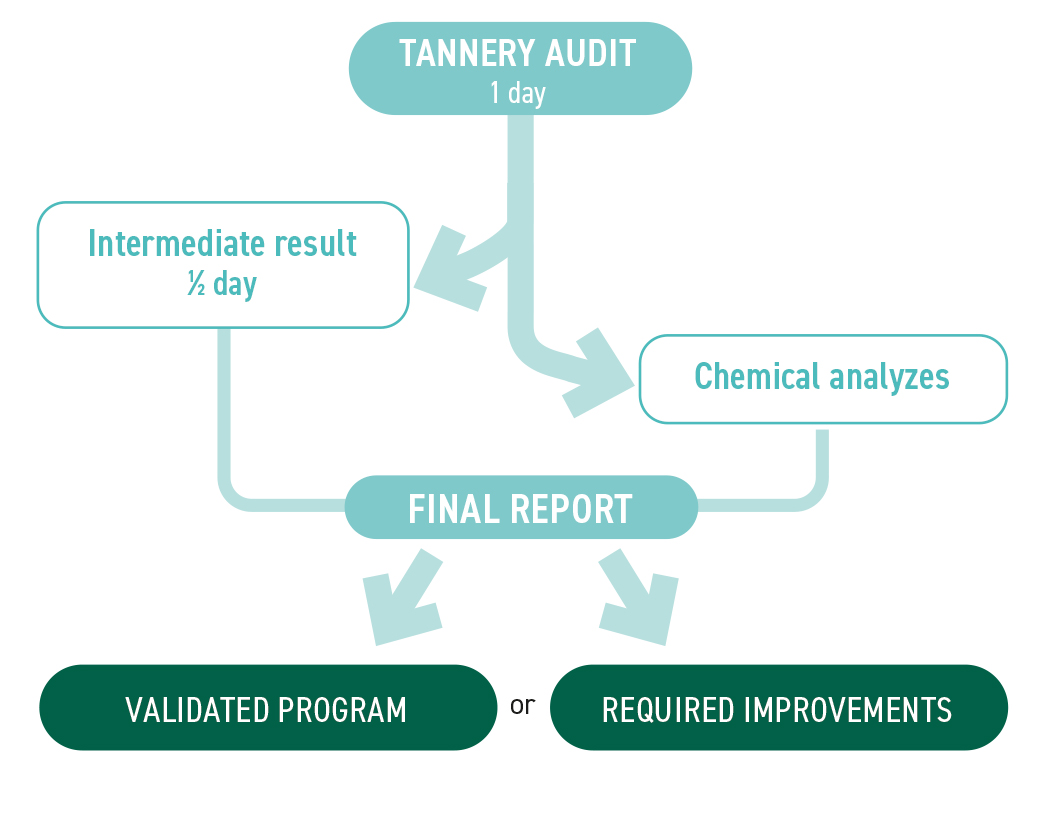

CTC proposes to check tannery processes to secured the market through a risk assessment methodology based on tannery audits.

It is a collaborative, continuous improvement process. This audit ensures compliance with good production practices so as not to generate hexavalent chromium (Chrome VI):

The tannery audit is a one-day audit within the tannery where the process is dissected from raw hide to finished leather. It is both a documentary and a field approach. It includes the assessment of chemical safety management, process and practices. It is also the opportunity to collect leather samples. 5 samples corresponding to 5 different articles are taken and sent to CTC analytical laboratory of chromium VI analyses with and without ageing.

Chromium 6 assessment Program by CTC

The day following the audit, the auditor give a presentation including information about the basis of chromium VI in leather and also the intermediate results of the audit. As the analytical results are not available at that time, it is only an intermediate result.

Chemical analyses included chromium VI analyses according to ISO 17075-2 standard without ageing and with ageing, both thermal ageing and UV ageing.

Combining field audit and analytical approach, the expert assessed and concludes on the conformity of the 5 leathers articles. Once it complies to the protocol, these leather articles are considered chrome VI assessed and the tanners signs the code of conduct.

In case of none achievement of the protocol minimum level, the audit system suggests improvement proposals.

If it is not enough, CTC proposes expertise for the improvement of the process.