- ABOUT CTC

- EXPERTISE AND SERVICES

- Raw hide - Tannery

- Footwear

- Leather goods - Glove-making

- PPE

- Environment

- CSR

- Training

- BLOG AND NEWS

- CTC VIDEOS

- LEAFLETS AND PUBLICATIONS

- CUSTOMERS EXTRANET

EN

Footwear protects the foot from the rough and the elements. Despite this, the foot is subject to significant stresses: it helps us to maintain our balance in a static position, it allows us to move around on all types of surfaces (flat or uneven, up or down stairs), and it must have the ability to respond to spontaneous accelerations.

During an activity, footwear must follow the motion of the foot: it must not counter, favour or amplify its natural movements.

Everything a consumer expects from footwear (mentioned above) is incorporated by the manufacturer into what is known as the fit.

The fit is decided by the design office and described in the product’s functional specifications. These take into account the specific needs of the individual and the activity concerned.

For a shoe to be comfortable to wear, it must correspond as closely as possible to the foot’s shape, it must also meet the requirements of the activity for which it is intended. There exists a wide variety of footwear ranges.

They are segmented for children, women, men and seniors, or by type of activity (sport, safety, etc.).

Our footwear specialists and laboratory experts are on hand to advise you about the types of tests best suited to your products and your needs.

| Test name | Criteria | Standard |

| Colour fastness to Rubbing (dry and wet) | Color fastness | EN ISO 17700 |

| Determination of water vapour permeability and absorption (mg/cm².h) | Comfort | EN 13515 - ISO 17699 |

| End point resistance | Mechanical resistance | NF G 62.013 |

| Flex resistance of the upper On Bally Flexometer | Mechanical resistance | EN ISO 17694 |

| Resistance to tear strength of upper | Mechanical resistance | EN ISO 17696 |

| Resistance to tensile strength and elongation | Mechanical resistance | EN ISO 17706 |

| Water resistance test On Bally Penetrometer | Comfort | EN ISO 17702 |

| Test name | Criteria | Standard |

| Colour fastness to Rubbing (dry and wet) | Color fastness | EN ISO 17700 |

| Determination of water vapour permeability and absorption (mg/cm².h) | Comfort | EN 13515 - ISO 17699 |

| End point resistance | Mechanical resistance | NF G 62.013 |

| Flex resistance of the upper On Bally Flexometer | Mechanical resistance | EN ISO 17694 |

| Resistance to tear strength of upper | Mechanical resistance | EN ISO 17696 |

| Resistance to tensile strength and elongation | Mechanical resistance | EN ISO 17706 |

| Water resistance test On Bally Penetrometer | Comfort | EN ISO 17702 |

| Test name | Criteria | Standard |

| Abrasion resistance | Mechanical risk PEE | EN ISO 20344 §6.12 EN ISO 20345 §5.5.3 |

| Abrasion resistance Martindale | Mechanical resistance | EN 13520 - ISO 17704 |

| Colour fastness to Rubbing (wet) | Color fastness | EN ISO 17700 |

| Determination of water vapour permeability and absorption (mg/cm².h) | Comfort | EN 13515 - ISO 17699 |

| Resistance to tear strength of upper | Mechanical resistance | EN ISO 17696 |

| Test name | Criteria | Standard |

| Colour fastness to Rubbing (wet) | Color fastness | EN ISO 17700 |

| Determination of water absorption | Comfort | EN ISO 22649 |

| Water absorption / desorption | Mechanical risk PEE | EN ISO 20344 §7.2 EN ISO 20345 §5.7.3 |

| Test name | Criteria | Standard |

| Abrasion resistance | Mechanical resistance | EN 12770 - ISO 20871 |

| Abrasion resistance | Mechanical risk PEE | EN ISO 20344 §8.4 EN ISO 20345 §5.8.4 |

| Bending resistance | Mechanical risk PEE | EN ISO 20344 §8.5 EN ISO 20344 §8.6 EN ISO 20345 §5.8.5 |

| Color fastness to ultra-violet Light | Color fastness | NF G 52 300 |

| Contact heat resistance (HRO) | Mechanical risk PEE | EN ISO 20344 §8.9 EN ISO 20345 §6.4.1 |

| Flex resistance | Mechanical resistance | EN ISO 17707 |

| Flex resistance (small size) | Mechanical resistance | ISO 132 |

| Hydrocarbon resistance (FO) | Mechanical risk PEE | EN ISO 20344 §8.8 EN ISO 20345 §6.4.2 |

| Insert perforation (P / PL / PS) | Mechanical risk PEE | EN ISO 20345 §6.2.1 |

| Resistance to tear strength | Mechanical resistance | EN 12771 - ISO 20872 |

| Resistance to tensile strength and elongation | Mechanical resistance | EN 12803 - ISO 22654 |

| Tear resistance | Mechanical risk PEE | EN ISO 20344 §8.3 EN ISO 20345 §5.8.3 |

| Test name | Criteria | Standard |

| Abrasion resistance | Mechanical resistance | EN 12770 - ISO 20871 |

| Abrasion resistance | Mechanical resistance | LHOMARGY - CTC Method - CTC-P-CH-017 |

| Top piece retention strength | Mechanical resistance | EN ISO 19958 |

| Test name | Criteria | Standard |

| Impact Resistance | Mechanical resistance | CTC method - CTC-P-CH-016 |

| Test name | Criteria | Standard |

| Abrasion resistance of shoe laces | Mechanical resistance | EN ISO 22774 |

| Accessories tear strength | Other tests | EN 71-1 |

| Aging zips | Mechanical resistance | EN 16732 Annexe F |

| Metallic accessories corrosion resistance | Other tests | EN ISO 22775 Méthode 2 |

| Side opening resistance of zipper | Mechanical resistance | EN 16732 Annexe G |

| Test name | Criteria | Standard |

| Antistatic footwear (A) | Mechanical risk PEE | EN ISO 20344 §5.13 EN ISO 20345 §6.2.2.2 |

| Behaviour of toecaps (thermal and chemical) | Mechanical risk PEE | EN ISO 20344 §5.6.2 EN ISO 20345 §5.3.2.5 |

| Cold insulation of outsole complex (CI) | Mechanical risk PEE | EN ISO 20344 §5.16 EN ISO 20345 §6.2.3.2 |

| Cut-resistant shoe (CR) | Mechanical risk PEE | EN 388:2018 EN ISO 20344 § 5.23 EN ISO 20345 §6.2.8.3 |

| Determination adhesion between midsole and outsole | Mechanical resistance | EN ISO 17708 |

| Determination adhesion between outsole and upper | Mechanical resistance | EN ISO 17708 |

| Determination of washability in domestic washing machine | Color fastness | EN ISO 19954 |

| Flex resistance whole shoes | Other tests | EN ISO 24266 Méthode A |

| Heat insulation of outsole complex (HI) | Mechanical risk PEE | EN ISO 20344 §5.15 EN ISO 20345 §6.2.3.1 |

| Heel energy absorption capacity (E) | Mechanical risk PEE | EN ISO 20344 §5.17 EN ISO 20345 §6.2.4 |

| Metatarsal protection (M) - Impact resistance | Mechanical risk PEE | EN ISO 20344 §5.20 EN ISO 20345 §6.2.6.2 |

| Reins of shoes | Other tests | CTC method - CTC-P-CH-009 |

| Slip resistance | Other tests | EN ISO 24267 |

| Slip resistance | Mechanical risk PEE | EN ISO 20344 §5.14 EN ISO 20344 §6.2.10 EN ISO 20345 §5.3.5 |

| Special ergonomic features | Mechanical risk PEE | EN ISO 20344 §5.1 EN ISO 20345 §5.3.4 |

| Toe protection - Crush resistance | Mechanical risk PEE | EN ISO 20344 §5.5 EN ISO 20345 §5.3.2.7 |

| Toe protection: impact resistance | Mechanical risk PEE | EN ISO 20344 §5.4 EN ISO 20345 §5.3.2.6 |

| Toecaps corrosion resistance | Mechanical risk PEE | EN ISO 20344 §5.6.2 EN ISO 20345 §5.3.2.4 |

| Upper/outsole bond strength | Mechanical risk PEE | EN ISO 20344 §5.2 EN ISO 20345 §5.3.1.2 |

| Water resistance (WR) | Mechanical risk PEE | EN ISO 20344 §5.19 EN ISO 20345 §6.2.5 |

| Waterproofing | Mechanical risk PEE | EN ISO 20344 §5.7 ISO 20345 §5.3.3 |

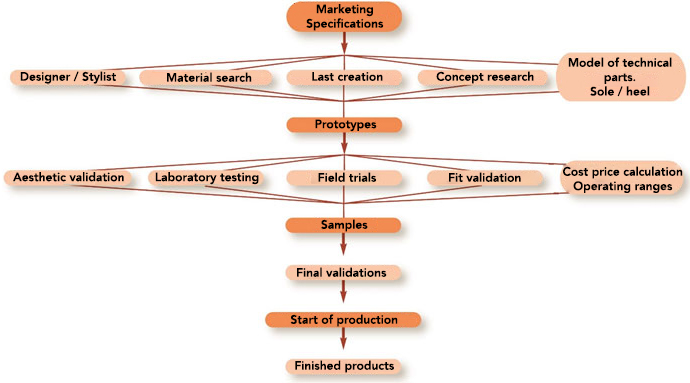

It may be hard for consumers to imagine the number of steps involved in making footwear, from the stylist or designer’s initial thought process to getting the finished products on the shop shelf. The process involves many different types of expertise, and the manufacturer must also work with a variety of suppliers.

The creation of a shoe is divided into several stages:

A shoe can be broken down into three main parts:

1. The upper, most often composed of the upper part and the lining

2. The assembly insole, covered by a sock liner

3. The sole, which is now increasingly composed of several materials.

To create, assemble and shape these three elements, we first need to create a fourth element: the last.

The volume of the last is close to that of the foot.