- ABOUT CTC

- EXPERTISE AND SERVICES

- Raw hide - Tannery

- Footwear

- Leather goods - Glove-making

- PPE

- Environment

- CSR

- Training

- BLOG AND NEWS

- CTC VIDEOS

- LEAFLETS AND PUBLICATIONS

- CUSTOMERS EXTRANET

EN

The first piece of equipment is a conveyor belt that measures the forces produced by the foot against the ground, thanks to two force platforms.

This belt allows for the measurement of the vertical, horizontal and mediolateral forces produced when the foot is in contact with the ground.

Use of the two force platforms located on each one of the two conveyor belts allows a differential analysis of right and left feet during walking. During running, there is no moment of double contact, thus only one platform need be used.

This system allows two different features be quantified with regard to shoes:

All types of footwear can thus be analysed and/or compared (sports shoes, shoes with heels, safety footwear, etc.).

Analysis of the impact of load bearing (backpack or handbag) on locomotion is also possible using this device. For instance, the changes in running pattern while carrying a backpack of varying weights can be quantified.

A number of studies have already been carried out measuring, for instance, new shock absorbing concepts, the stability produced by various shoes or even how older people walk in shoes with heels.

This belt is embedded in the ground and thus allows non-linear movements to be tested (lateral movements, for instance) and also permits the study of people for whom use of a conveyor can be risky (children walking or seniors running, for example).

A motion analysis system comprising six cameras allows cinematic analysis to be carried out. Thanks to this system, reconstructions of movement, or of the product, can be done in three dimensions.

With regard to motion analysis, by means of markers attached to the testers, we can measure various joint angles, and quantify the accelerations or speeds of certain segments, etc.

In terms of product analysis, motion analysis allows us to show in precise detail how the product (or a part of it) moves under conditions of use. These data are crucial for understanding the effects of products on the human body, so that we can then make the appropriate modifications. Integrating these measurement tools on test machines or beds could also prove interesting. Finally, changes in the way different groups move (seniors, children, people with diseases, etc.) can also be measured.

This measurement system has already allowed us to quantify the stability of runners while they wore various types of running shoes, through observation of the tibia-calcaneal angle.

The precise trajectoried describes by handbags while being carried by various individuals were also identified.

These two systems are “heavy” biomechanical tools, which cannot be removed from the CTC laboratory in Lyon.

A motion analysis system coupled with a force platform is also available. This system combines the two aforementioned types of measurement (force measurement and motion analysis system). However, the MiniLab only allows measurements to be taken at the level of the foot and the leg, as far as the calf. The upper limb is not taken into consideration with this tool.

This piece of equipment is portable, so it can be used to carry out measurements in the field.

This device allows the measurement of weight distribution, maximum pressure levels, contact surfaces, etc.

It is made up of different pressure pads allowing these analyses to be done.

The pressure pads can be placed directly into the shoe, in contact with the lining, the objective in post cases being to obtain a reading of how different linings affect the way pressure is distributed. The notion of (underfoot) “comfort”, which is overwhelming, can be approached using these measurements of plantar pressure.

Studies have been done in order to quantify maximum differences of pressure (zones of potential discomfort) and surface contact. Lining materials have also been tested.

This system also provides for the use of pressure sensors of differing sizes. For example, we have a pad capable of measuring pressure on the hands of testers. This pad is mainly used in the area of workstation ergonomics in order to measure exertion during gripping. It is completely suitable for characterising what happens when people are gripping things such as rackets, handles, etc.

Finally, other pads allow the measurement of how pressure varies across large surfaces, like the backs of horses, seats of chairs, and bicycle or motorbike saddles.

In the area of leather goods, pressure analysis can also be very instructive when it comes to product design. For example, the varying pressures put on the shoulder while carrying handbags fitted with different straps can be studied.

The way pressure is distributed across the back and shoulders while carrying different backpacks can be measured.

This system is portable and manageable. It can function using Wi-Fi (200m range) and thus facilitates various types of analysis in the field.

The ME 6000 is a device allowing three types of measurement to be made:

The ME 6000 allows the analysis of muscular effort by means of electromyographic measurements. This works by placing electrodes on the chosen muscle in order to quantify its activity during a given task.

The device allows up to 16 muscles to be measured at once.

This type of analysis is used in ergonomics in order to quantify the effort made during various work cycles.

EMG also enables the impact of products on the human body to be measured (distinguishing between types of shoes or the weight of various load being carried). EMG analysis can be carried out on muscles of the lower limb in order to compare different shoes with regard to how tiring or stable they are.

Goniometric measurement enable joint angles to be quantified by means of a goniometer.

This measurement allows quantification of parameters, such as locomotion, while wearing different shoes (angle of the hip, knee or ankle). Thus, impact of different joint amplitudes in the knee and ankle while walking in high heels has been measured among senior citizens.

The effect on joint amplitudes at shoulder level carrying handbags in different ways (with a shoulder strap, in the hand, on the elbow) has also been studied.

Using an accelerometer allows us to quantify accelerations and also to determine the speed and the position of a part of the body or a product. These sensors are small in size and can easily be placed in various places: on the human body (hand, arm, head, leg, etc.) on a product (shoe, bag, etc.).

The use of this type of sensor also permits the measurement of impact produced while running depending on the shoes being tested. The shock wave (vertical acceleration) transmitted to the lower limb as the foot hits the ground can be measured by means of these accelerometers. The greater the acceleration, the greater the impact.

The ME 6000 thus allows these three types of measurements to be synchronised. It also has Wi-Fi functionality and is fitted with a data acquisition card. Subjects can thus take measurements in the field. Data is saved, then downloaded when the device is next connected. In addition, this system is unobtrusive for users. A simple belt allows the information to be stored; the sensors are attached by means of cables, which are easily disguised.

More Information about research & development services of CTC

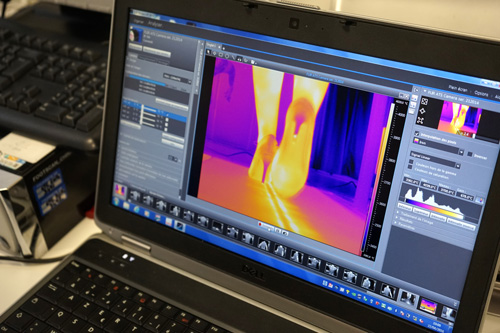

The CTC Biomechanics Laboratory also comes with an infrared camera allowing heat exchanges to be measured.

This camera allowed us, for instance, to measure the increase in temperature of a shoe sole during physical activity, with shifts in weight.

This camera can also identify differences in temperature related to wearing different textiles (breathable T-shirts, etc.).

Finally, thanks to the infrared camera we can locate target areas (heat loss, heat absorption, etc.), by analysing differences in temperature.

High frequency cameras enable slow-motion filming, the goal being to be able to analyse movements that are too fast for the naked eye to see. The sampling frequency of this type of camera is greater than 1000Hz.

We are able, for instance, to measure the compression levels of the outer soles of different running shoes. Sudden movements can also be analysed (falls on testing equipment).

In order to quantify the overall energy consumption of the body, CTC is equipped with a system for analysing exchanges of O2 and CO2 gases.

The MétaMax 3B is also used in ergonomics at the level of the workstation in order to quantify energy expended in the carrying out of given tasks. This system has been used in a tannery environment on workstations that are rather physically demanding. For example, the advantages of wearing an exoskeleton on this type of task is going to be measured thanks to the MétaMax 3B.

The system is made up of a mask that allows the air that has been inhaled and exhaled to be gathered, and is fitted with an analysis and processing module directly attached to the testers.

It enables a performance in an endurance sport to be measured and, specifically, allows the VO2 max of sportspersons to be determined with precision.

In conclusion, CTC puts at your disposal a large number of biomechanical tools. Product differentiation, proofs of new designs, innovation, ergonomic analysis, as well as assessment of the advantages of workstation solutions can all be measured thanks to these various tools.

Various research projects have also been conducted thanks to this biomechanical platform. A benchmarking of running shoes has been carried out, advances in physical test beds have also emerged, and analyses involving particular groups, such as senior citizens, have been made. Finally, biomechanical measurements are carried out directly on a panel of testers carefully selected depending on the product being tested or the study been conducted. A minimum of 10 people is required to be able to precisely identify potential differences. Thus, this type of measurement demands a significant investment, but is however eligible for research tax credit. Please do not hesitate to contact our innovation department (Département Innovation Technologique) should you require any further information.

More Information about research & development services of CTC