- ABOUT CTC

- EXPERTISE AND SERVICES

- Raw hide - Tannery

- Footwear

- Leather goods - Glove-making

- PPE

- Environment

- CSR

- Training

- BLOG AND NEWS

- CTC VIDEOS

- LEAFLETS AND PUBLICATIONS

- CUSTOMERS EXTRANET

EN

In a context where hides with only few defects are rare, it is important to improve the quality of leather through sustainable corrective actions, from the birth of the animal to the tannery, including transport, flaying and conservation.

CTC has developed and implemented a comprehensive solution with multiple benefits:

The comprehensive solution we have designed and developed and are currently industrializing and implementing can be broken down into four phases.

Ideally, the system relies on the meat traceability requirements that are enforced in most industrialized countries. Where there are none, slaughterhouses can generate a unit identification code. Our solution’s first phase therefore consists in transferring this unitary identification number from the animal to the hide. This phase must take place on the slaughter line before the flaying station, so as to reliably keep the traceability chain continuous.

***

"A range of unique industrial

tools ensuring reliable,

simple and economically

viable traceability."

***

There are two options:

The cost of this equipment is relatively low (less than €4k) and the cost of consumables is very low (under €0.067 excl. VAT per printed label).

This first phase allows small slaughterhouses to transfer meat traceability onto hides so as to provide reliably traceable hides to their clients at an economically viable cost, and also allows large slaughterhouses to ensure the continuity of traceability between the slaughter lines and the salting workshop where hides can be marked at their core.

We were quick to notice that no label or matter added on the hide could resist the tannery entry process (wet work / tanning), which means the unit mark must be copied into the core of the material. We have therefore opted to transfer it there by means of an innovative technology that fits right into our industry – laser marking.

CTC has developed a high-power CO2 laser marking system. Transferring a 14-character code to the core of the hide by marking on the hair side takes a few seconds. This duration makes it possible to fully automate the operation and complete it in a masked time, during the process of salting or sorting raw hides.

After several studies, it was agreed that the best area for marking was on the shoulder, 15 cm to the left of the back line and 10 cm below the hide’s edge.

The cost of the industrial system deployed in several French slaughterhouses and tanneries ranges from €100k to €150k depending on the level of automation and integration chosen.

The marking process has proved itself on bovine leather (ranging from calf to bull) and exotic hides (alligator, snake), and tests are underway on lamb hides. This operation can be carried out at all stages from the extraction of the hide on the slaughter line to tannery entry if the hide bears a label as previously described.

Another crucial point in the success of this solution is the form and nature of the marked code. This code must respect a strict typology defined in terms of:

All these settings are crucial to achieve very high automatic reading rates in the next phase.

After tanning, each skin is inspected. During the feasibility study, it was possible for an operator to read and copy the hide’s unit code and note down any defects along with it. This process cannot realistically be exported to an industrial operation, as it would both take too long and lack reliability. CTC has therefore developed automatic mark reading stations, for use during the sorting operation at the tanned stage (wet-blue, wet-white) first, and then at later stages of the process.

For this purpose, we have developed various leather image acquisition stations to suit the different configurations of sorting stations at each tannery. To date, we have three types of acquisition station (to capture images of the marked area), all of which use algorithms based on artificial intelligence (specifically neural networks). We could have used more common OCR-type image processing algorithms but the results would not have met expectations.

The solution developed by CTC makes it possible to recognize alphanumeric characters set in the hide, even when they were only partially marked or were warped during tanning. This integrated intelligence allows perfect reading rates to be achieved for more than 90% of production.

With a well built base, this approach allows for better efficiency than human operators could achieve in deciphering marks. AI makes it possible to adapt to the vast variations in the quality of markings that result from the processes of individual tanneries.

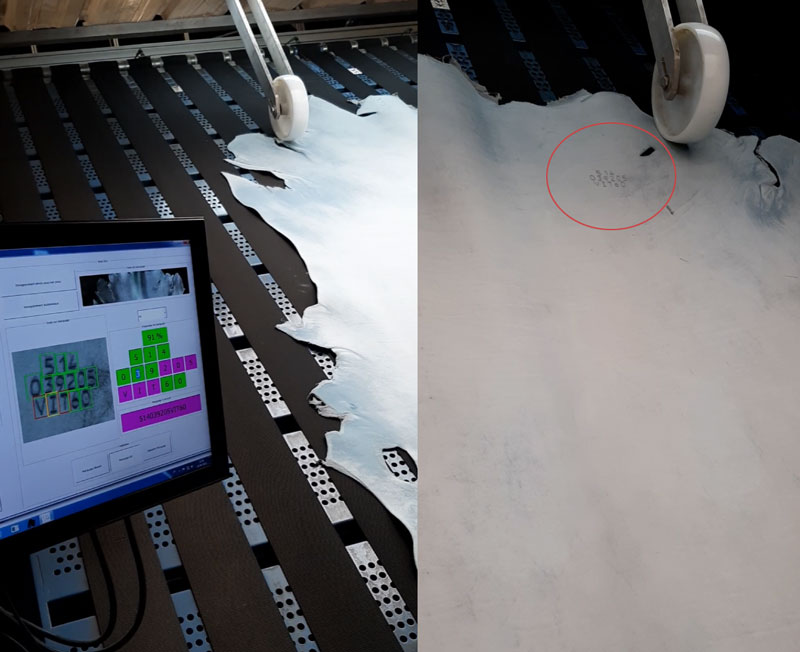

The first acquisition station, which is the least technically complex, allowed us to carry out the feasibility study and algorithmic modeling.

It is composed of an area scan camera and a portable grazing light. The operator places this station on the mark and presses a button to trigger the image capture. The system then automatically locates and rotates the mark, decodes all the characters, and sends it to a piece of software to be associated with the defects found on the hide.

The second acquisition station, which is fully automated, is designed for tanners equipped with a conveyor and an automatic stacker unit for sorting. Each hide passes under a linear camera and a grazing light, allowing for an image of the whole hide to be reconstructed, and the algorithms then automatically search for the mark, rotate it and decode it to store the code in a database.

Our latest acquisition station, which is also fully automated, is intended for tanneries that sort hides piled on a pallet placed on a lifting table in front of the sorter. This station consists of a simple very high resolution area scan camera and a specific light, it scans the shoulder and the entire decoding operation is carried out by artificial intelligence algorithms that adapt to changes in image capture conditions over the course of the sorting operation. The feasibility study for this station is currently coming to an end and had yielded promising results.

In all cases, algorithmic processing takes about a second, which is much less time than is needed to sort a wet-blue and determine its quality potential.

Following this series of studies, a harmonization phase allowed us to generalize the algorithm to all acquisition stations; this algorithm is improved as the learning progresses, thus ensuring that our solution is optimal and scalable over time.

This technology can also be applied to exotic hides, so as to transfer the CITES ring’s code to the core of the material and remove the ring itself, thus making it possible to work on the entire hide on through machines.

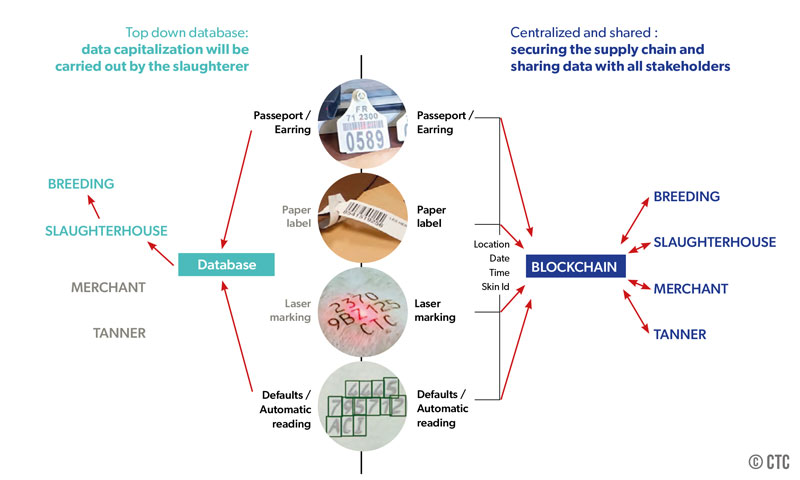

The last phase of the proposed comprehensive solution is to set up a data management system.

To do so, we currently offer two solutions:

This "Raw material quality" data architecture, combined with a single and complete tracking solution going back to the animal’s birth, opens up possibilities to implement quality charters specifying the origin of raw materials and providing information pertaining to animal welfare,

In addition, many types of information pertaining to the craft could also be integrated to this blockchain, like for instance, the dates of interventions for corrective actions or notes on defects found on wet-blues.

This type of implementation (regular or blockchain database) makes it possible to meet all of the traceability project’s goals (improvement of hide quality, animal welfare, origin of hides and full monitoring of the supply chain).

This research and development project conducted by CTC at the request of the French leather industry has provided the industry with a range of unique industrial tools ensuring reliable, simple and economically viable traceability. These tools are undeniably crucial building blocks for the implementation of corrective actions aimed at sustainably improving hide quality, as well as the implementation of charters to guarantee and secure hide supply sources while respecting animal welfare. These elements are the foundations of an eco-responsible supply chain.